Precision ground steel

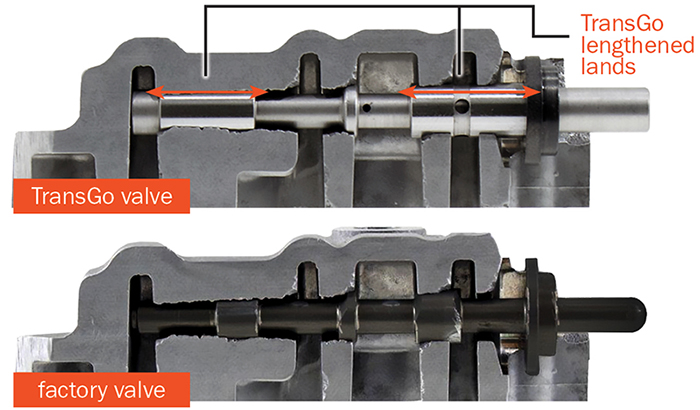

As OEMs strive to meet federal CAFÉ requirements, many utilize anodized aluminum valves in their automatic transmissions. However, this type of valve is susceptible to root cause failures due to delamination of the anodized coating from the valve lands, leading to instability and hang-ups in the bore, reducing the overall performance and reliability of the transmission system.

TransGo offers a technical solution with their precision-ground US-made steel valves, designed to resist delamination and provide a long-term, high-quality upgrade to the transmission system. Steel valves eliminate the risk of valve hang-ups in the bore, ensuring smooth operation and improved performance.

Made in the USA

TransGo has a long-standing commitment to quality and reliability, and has been proudly manufacturing its products in the USA for over 65 years. The company takes great pride in using only the finest materials and state-of-the-art technology in its manufacturing process, ensuring that each product meets the highest standards of performance and reliability. With a team of experienced engineers and technicians, TransGo is dedicated to providing the best solutions for the automotive industry, and continuously strives to innovate and improve its products. By manufacturing in the USA, TransGo is able to closely monitor every aspect of production and ensure the highest level of quality for its customers.